“When the product is right, you don’t have to be a great Marketer.” Lee Iacocca.

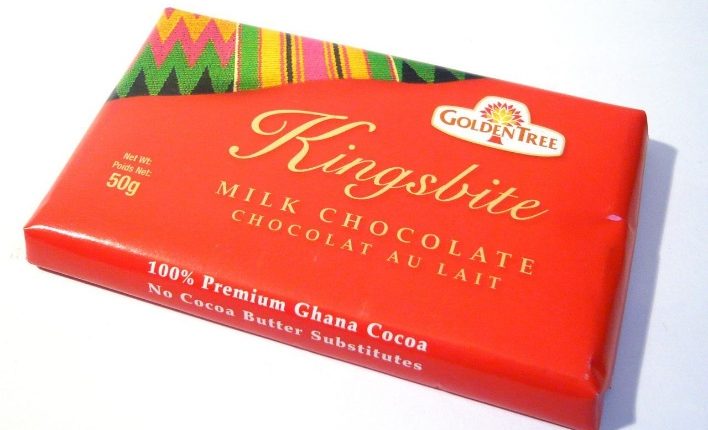

Welcoming my little girl from the United Kingdom to spend her vacation in Ghana, I got to the airport with a box of chocolate to calm her nerves after a long flight and also give her a welcoming feel. Our ride home was taken over by a chocolate discussion after she opened one Kingsbite and had a queen’s bite.

Her outburst after the bite, “is this made in Ghana? It’s not big though but very tasty “. I can taste the cocoa unlike the huge bars available in my country with very high suger and milk content”. This expression about Ghana’s chocolate speaks volumes and must not be taken for granted.

Ghana has for over a century carved a respectable reputation worldwide as the producer of the finest quality cocoa beans rated second to its neighbour, Ivory Coast, in the production of cocoa beans with the two West African nations accounting for more than 65 percent of annual global output.

Cocoa growers in Ghana use natural and traditional methods of fermentation and drying after harvesting their cocoa, which leads to a higher quality bean and more complex flavour than the mechanized methods that are used in some other places. That said, it is undeniably true that Ghana’s chocolate with a strong cocoa character has an appealing taste for the chocolate experience.

Here in Ghana, Cocoa processing Company, the sole cocoa processing factory in the sub- region which can boast of processing only the choicest premium Ghanaian cocoa beans without any blending is certainly the world’s best established in 1965 with the aim of projecting healthy lifestyles and also producing international quality standards for consumer satisfaction.

“The health and wellness of our people is our paramount goal hence our Company’s insistence on using 100% cocoa butter in its chocolate manufacturing without any substitutes. Our Goldentree Chocolates also have a higher percentage of cocoa solids. It must be noted, that not many chocolate products on the market can claim the above credentials”. Mr. James Rhule, Head of Communications & Corporate Social Responsibility of Cocoa processing Company stated.

According to Mr. Rhule, most chocolate manufacturers across the world source their raw materials from CPC and have over the years attested to the quality of the Company’s cocoa products such as, Cocoa liquor, butter and powder.

Ghana’s chocolate has found its way into diverse market spaces across the West African sub-region including the neighbouring Togo, Benin, Nigeria and Ivory Coast as well as Senegal and Sierra Leone.

You can also find the Golden tree chocolate in African shops in the UK and the US while about 90% of our semi-finished products namely, Cocoa liquor, butter, cake and powder are exported to the Netherlands, Belgium and other Asian countries

Getting finished products such as our Golden Tree Ghanaian chocolate bars into the international markets though a herculean task owing to non-tariff barriers used across the world by industrialized countries to protect local industries against foreign competitions including licenses, quotas, embargoes, foreign exchange restrictions and import deposits compounds exports woes.

A Ghanaian based in the UK while in Ghana tried exporting the Ghanaian chocolates to the UK successfully but the product got misplaced on arrival at the UK. To make this dream of exporting the Golden tree chocolate possible, he used his wife who is an American to buy the product to America, got it melted in her small chocolate factory and repackaged for the American market.

Another American entrepreneur of Ghanaian origin “Omanhehe” also able to get the Ghanaian Chocolate into the International market by providing his company approved packaging materials to the Cocoa Processing Company for exports while others use agents to sneak products into forign markets.

Exporting 95% of its raw materials ranging from the cocoa liquor, butter, natural/ Alkalized cake or powder, Ghana remains the world best potent chocolate producer, identified on the World market performing chart-index as the second largest in the world which also is the most expensive, giving its quality and health benefits.

In processing the cocoa beans to a semi-finished product, out springs the Cocoa Liquor which is 65% fats from which the cocoa butter is extracted with the residue referred to as the cocoa cake grounded to get the cocoa powder.

From its raw materials, the Company supplies potassium to soap and body cream manufacturers and also use the cocoa shells as manure procured by farmers to help nourish and boost their farm produce while the liquor residue finds its way into pharmaceuticals to help underweight patients gain weight, stimulate the nervous systems of weak people, calm hyperactive people and improve digestion and kidney functions.

Every fragment of the cocoa is useful. The shells, for instance are used as manure for farming purposes while local soap manufacturers burn them to extract potash for soap making.

Other Jurisdictions have polished fancy bowls and other fabricated usables emanating from cocoa residues contributing greatly to economic prospects which can be enhanced with adequate government support through production expansion capacity of CPC to engage more hands, augment and produce more raw materials and finished products for a greater market, jobs and healthy livelihoods.

Cocoa Processing Company (CPC) employs over 300 staff and provides employment opportunities for other private individuals in the cocoa/chocolate value chain namely transporting of cocoa beans to the factory, packaging, marketing and sales etc.

“To ensure the quality and safety of our chocolate products we go through rigorous processes in choosing distributors which includes inspecting their shops or warehouses to assess their suitability for chocolate storage and sales”. This was according to Mr. Rhule.

Take a bite and keep up health.

By: Mabel Delassie Awuku

The writer is a staff of the Information Services Department (ISD)

Comments are closed.